Industrial hygiene specializes in the recognition, evaluation, and control of hazards in the workplace and public environments. An exposure assessment is the primary tool used to determine what hazards are present, how these hazards are impacting people, and what solutions are most practical to mitigate their impacts. Understanding the types of exposures occurring in your workplace or public environment is key to protecting the health and well-being of individuals using the space.

Aura professionals are experienced in conducting exposure assessments for a variety of hazards including:

Biological – allergens, bacteria, fungi, viruses

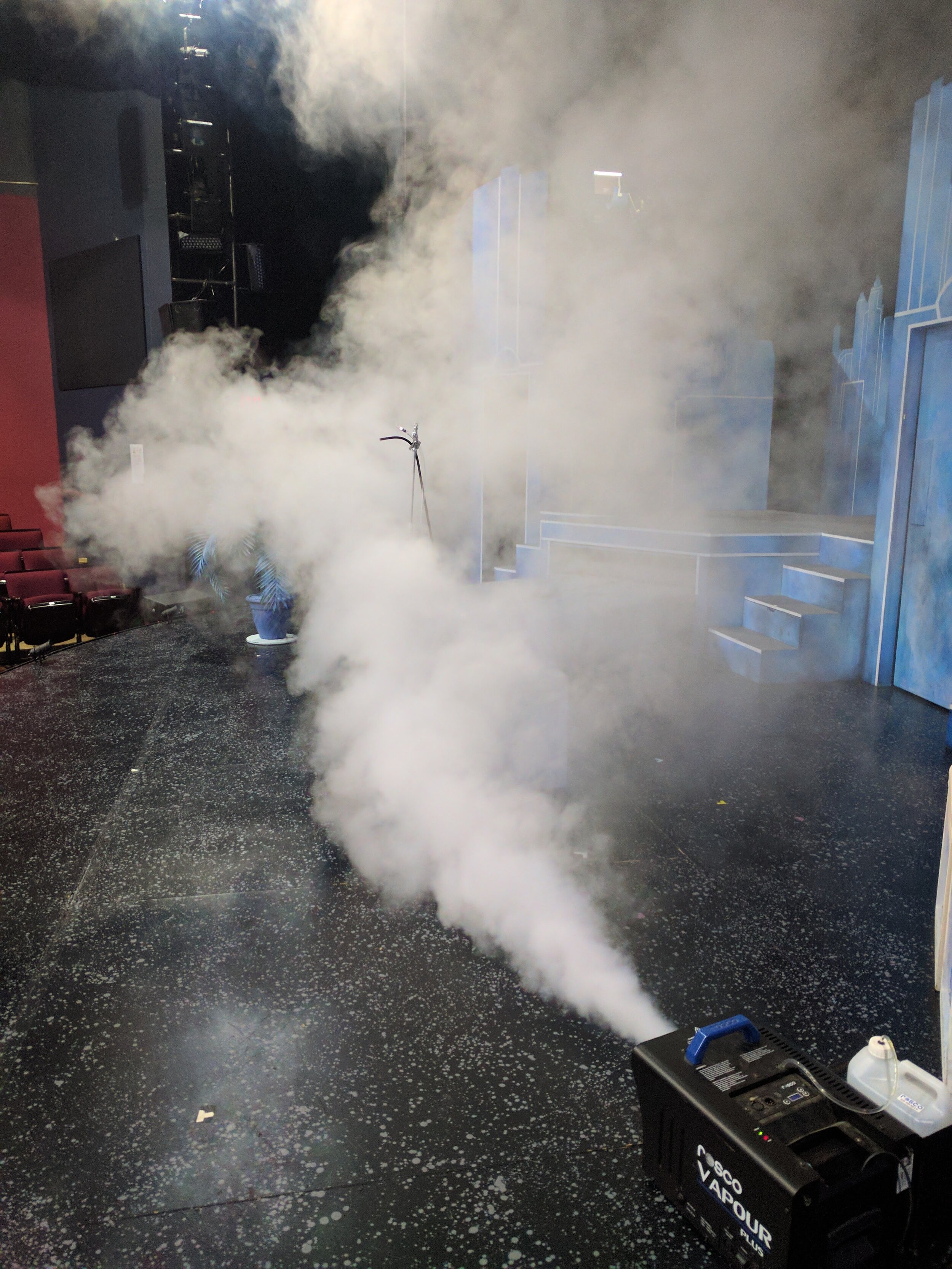

Chemical – asbestos, atmospheric fog, gases, heavy metals, isocyanates, lead, silica, welding fume metals, volatile organic compounds

Physical – cold stress, ergonomics, heat stress, ionizing radiation, non-ionizing radiation including electric and magnetic fields (EMF) and radiofrequency fields (RF), noise

Aura personalizes exposure assessments to the needs of each client. We first discuss your situation with you to understand your circumstances and objectives. Next, we develop a personalized exposure assessment that meets regulatory requirements and your objectives. With our experienced team of Industrial Hygienists, we professionally conduct the exposure assessment and provide you with results that will make a difference to your employees and workplace. Aura services all types of employers and workplaces, from schools and hospitals to industrial manufacturers and resource developers. Whether you are a local or international company, Aura has the technical capabilities and experience to help you achieve a safer workplace.

Stories from the Field

Aura Industrial Hygienist, Matthew, worked with a resource developer to create a unique exposure assessment plan to investigate worker exposures to welding fume and respirable crystalline silica at their worksite. In collaboration with the Client, an 8-day sampling campaign was developed to achieve the Client’s objectives. Matthew travelled to the worksite and conducted personal and area full-shift monitoring for the identified hazards while providing additional knowledge translation to employees and supervisors. The work performed culminated in a greater understanding of workers’ exposure to welding fume and silica and provided actionable steps to help mitigate these hazards in the future.